XConnect® RAIL has prioritized SIMPLICITY and EFFICIENCY while providing a COST EFFECTIVE, RELIABLE solution for your active oriented perforating operations.

INCREASED EFFICIENCY AND RELIABILITY:

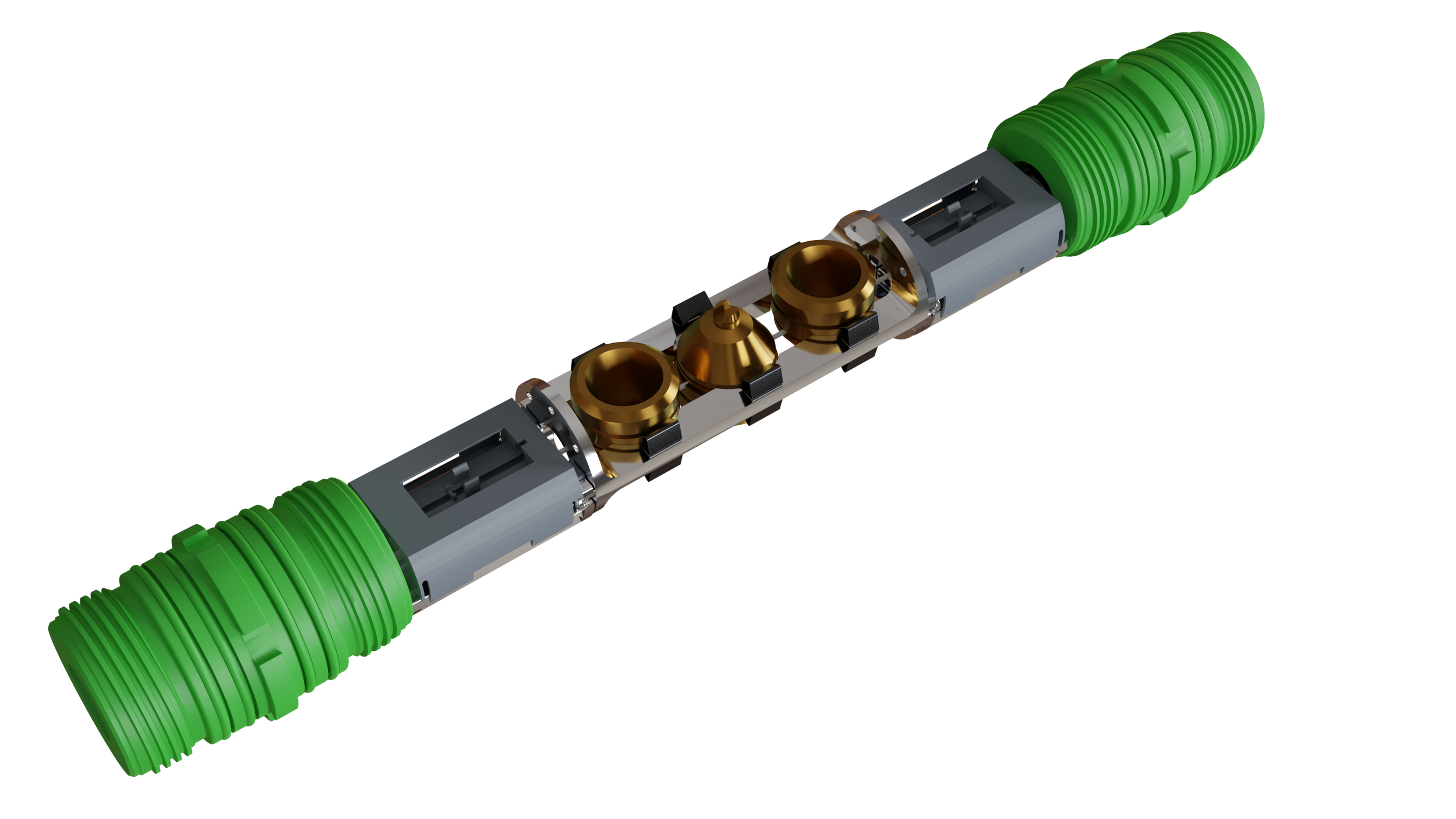

Industry Leading Electrical Grounding capable of handling lateral loads and continuous perforating shock.

Ball Bearings (competition) have been replaced with Tapered Roller Bearings to provide superior ground connectivity due to the larger surface area. Tapered Roller Bearings capable of exceeding 3000 lbs of lateral loading.

COST-EFFECTIVE:

Leverage existing and proven XConnect® components to maximize cost savings to customers.

Barrels and various components are compatible with our XConnect and LynX system.

(Approximately 1,000,000 barrels shot and counting. )Current design is capable of 1-2-3 shot configuration.

Pre-wired molded insulators enable precise and efficient assembly.

“CLICK-IN” charge holder designed for most charges in the industry.

Compared to conventional charge tube, RAIL “CLICK-IN” design increases accuracy of charge orientation.

Detonation Cord Management leads the industry in simple hassle-free installation.

FIELD OPERATION BENEFITS:

FULLY Disposable.

FULLY LOADED and ALIGNED to customer specs.

NO sub rebuild kits.

Factory installed Subs and Switch.

Install det and thread to the previous gun.

NO PIPE WRENCHES.

RAIL Sub compatible with XConnect® Assembly Socket design